Pharmaceutical Clean Rooms

Maintaining clean room environments

The use of air pressure stabilisers is proven to protect the sterility of pharmaceutical clean rooms and manufacturing facilities. Maintaining differential air pressure controls the transfer of airborne contaminants.

Clean Rooms

(MHRA – The Orange Guide 2017)

Pharmaceutical manufacturing facilities

Pharmaceutical companies must maintain a pressure differential of 10 – 15 pascals between the manufacturing area and the pressure in the adjacent surrounding facility areas.

For information on the latest rules and guidance on Pharmaceutical Manufacturers, you can refer to the MHRA – The Orange Guide 2017 which has all the answers you need to stay informed.

Research Laboratories and Electronics Production Facilities (ISO 14644-1:2015)

Apreco have been involved in some very prestigious facilities where cleanrooms are being controlled with our Air Pressure Stabilisers to assist in meeting the requirements of these facilities designed adhering to ISO room classifications. ISO 14644-1:2015 specifies the cleanliness of air in relation to airborne particles in clean rooms.

Apreco’s Air Pressure Stabilisers are ideal for controlling the differential pressures between areas as well as moving the air volume from one zone to another.

View ProductsMaintain Reliable Air Pressure Control

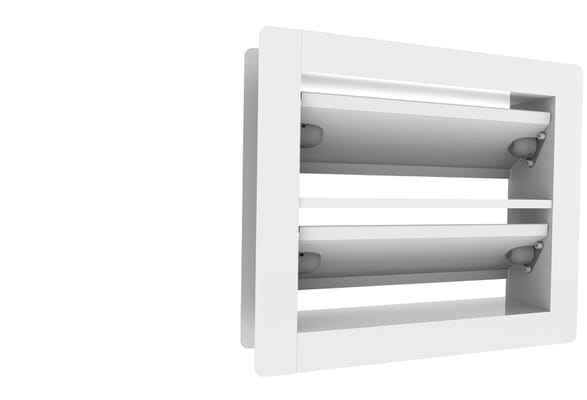

Air Pressure stabilisers

The VARI-Centric® range of Air Pressure Stabilisers featuring the Easi-release™ blade system are continuously safeguarding and protecting laboratory and pharmaceutical facilities from airborne contamination around the globe.

Product Range