Air Pressure Stabilisers

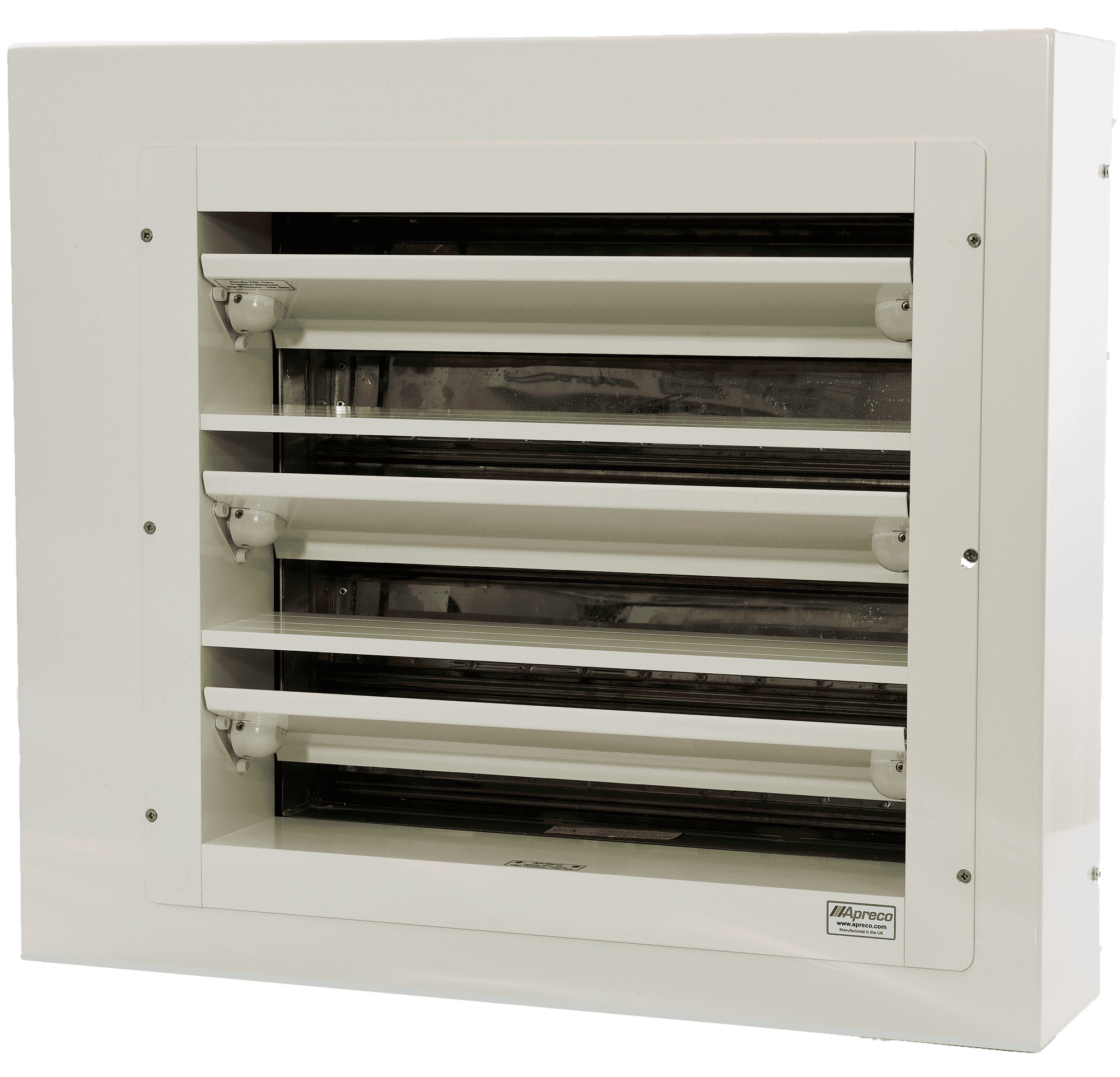

APSX®-FSS Smoke Fire Rated Air Pressure Stabiliser

-

- ISO 9001

- Serial Number Traceability

- Incorporating VARI-Fix® system

- Patent No. GB 2600994

- Encased within Smoke/Fire Damper

- Antimicrobial protection

Get a quoteThe APSX®-FSS Smoke Fire-Rated Air Pressure Stabiliser has been added to the Apreco range following extensive feedback from the healthcare market and is encased within a smoke fire damper. The need to protect patients and staff in the event of a fire is of paramount importance, our new APSX®-FSS with its sleek compact design has been well received from Clients, Designers and Infection Control personnel.

The design philosophy behind the APSX®-FSS has been developed following consultation with M&E consultants and contractors with the assistance of Warrington Fire; world-renowned experts in the testing of fire/smoke rated products for the construction industry.

We looked at the current testing approach to combined air pressure stabiliser fire/smoke damper products and concluded that they are generally not covered by BS EN 1366-2:2015 which, relates to the ability of a fire damper to prevent fire and smoke spreading from one compartment to another through the ‘air ductwork systems’. It was agreed that the better approach being more aligned to the application where the air pressure stabilisers are installed in walls (i.e. no ductwork present) was to utilise BS EN 1364-5:2017 for fire resistance tests for non-loadbearing elements. The smoke leakage test was then based around BS476-31-1: 1983 covering smoke control tests for doors and shutter assemblies.

It is important to understand that air pressure stabiliser’s primary function is to provide ‘door’ flow protection and are therefore by definition invariably located next to a door with a 30 or 60-minute fire rating and not in the air ductwork system. The Air Pressure Stabiliser is therefore acting more as an Air Transfer Grille than a Damper. So, in conclusion, to supply a product tested in a manner for the environment it was designed for, we have adopted the following test protocols to evaluate the APSX®-FSS: Fire Integrity Test to BS EN 1364-5: 2017 (WarringtonFire Test 412865), Smoke Leakage Test to BS476-31-1: 1983 (WarringtonFire Test WYC417772).

The VARI-centric® range of Pressure Stabilisers is purpose-designed for Operating Theatre Suites to control airborne contamination by controlling room pressure differentials and has recently been installed as part of the operating theatre refurbishment at Queen Elizabeth.

Fire Integrity Test installation of APSX®-FSS at Element Warrington Fire

Fire Integrity Test installation of APSX®-FSS at Element Warrington FireThe APSX Air Pressure Stabiliser has been purpose-designed for the application of differential air pressure, such as Operating Theatres, Isolation Rooms and Pharmaceutical Clean rooms to control airborne contamination.

The VARI-centric® balancing system accurately controls the differential air pressure between adjacent rooms, with the blades closing fully as soon as the pressure differential drops below the required level. This diverts the airflow to pass through an open door forcing back airborne contamination without the need to alter the air extract and supply.

Positive pressurisation of Operating Theatres to protect them from the ingress of infectious agents passing through the open doors, by providing high air volume rates, is a well-established principle of hygiene and infection control, forming the fundamental principles on which Health Technical Memoranda HTM 03-01 is based.

Apreco VARI-centric® Pressure Stabilisers and associated products are supplied as standard with Biomaster antimicrobial paint finish, utilising silver technology – which is already used extensively within the healthcare sector as an excellent antimicrobial protection in conjunction with good hygiene practices. Biomaster is extremely effective in helping to protect against harmful bacteria including MRSA, Ecoli, Salmonella and C-diff.

Patent No. GB 2600994

-

Operating Theatres

The APSX®-FSS Smoke Fire Rated Air Pressure Stabiliser is utilised to maintain the positive pressurisation of operating theatres and isolation rooms, to protect them from the ingress of infectious agents passing through open doors by providing high air volume flow rates is a well-established principle of hygiene and infection control.

Apreco has been acknowledged for their assistance in contributing to Health Technical Memorandum (HTM 03-01) which supercedes HTM 2025. They have also assisted with the validation of Isolation Room design following Health Building Notes (HBN 4: Supplement 1).

Clean Rooms

Apreco’s APSX®-FSS Smoke Fire Rated Air Pressure Stabiliser has been designed to maintain differential pressure control within sterile environments. Our range of products are employed within pharmaceutical clean rooms, manufacturing facilities, research laboratories and electronic production facilities worldwide.

All cleanroom areas should be either classified or non-classified. All classified areas should conform to an applicable standard. This standard is dependant upon geographic location and usage.

Isolation Rooms

When following the guidelines of HBN4 Supplement 1: Isolation facilities in acute settings the APSX®-FSS Smoke Fire-Rated Air Pressure Stabiliser is utilised to maintain the positive pressurisation lobby ensuring that air from the corridor does not enter the isolation room, and that air from the room does not escape into the corridor.

This basic but effective design enables the suite to be used for both source and protective isolation without the need for switchable ventilation or special training for staff. Importantly it also provides safe isolation for those patients whose exact condition is unknown.

-

Metric Selection

The method below will give you an indication of the size of unit required for a given volume flow-rate at a given pressure.

Use Table A to calculate the total length of blade required, and then divide it into sections of equal length using values from Table B.

Example:

Selecting a Pressure Stabiliser capable of transferring 310 l/s (0.31 m3/s) @ 5 Pa.Stage 1:

310 x 7.35 = 2278.5 mm of total blade length.Where: 310 = Volume in l/s and 7.35 = Factor from Table A relating to 5 Pa.Stage 2:

Divide the calculated total blade length into equal lengths using one of the standard blade lengths from Table B.Consideration should be made regarding any physical restrictions that the building may impose before selecting the blade length for the unit.

Total calculated blade length of 2278.5 divided by 4 blades = 569.63 mm.

Rounded up to the nearest standard blade increment from Table B gives you 4 x 575 blades.

Table A (Factors)

Pa Factor Pa Factor 5 7.35 17 3.98 10 5.20 20 3.68 15 4.25 25 3.29 Table B (Blade Lengths in mm)

200 350 500 625 250 400 550 675 300 450 575 750 Nominal Height:

Single Row (Base Unit) = 123mm.

Height of each additional row = +133mm per row. -

X-Ray Protection Screen

Apreco provide purpose designed lead-lined screens mounted in front of the stabiliser to protect personnel from harmful X-rays.

Laser Protection Screen

Apreco provide purpose designed screens mounted in front of the stabiliser to protect personnel from harmful laser-rays.

Air Baffle Screen

The Baffle Screen has been designed to divert the air from the Bespoke Air Pressure Stabilisers reducing jetting whilst allowing the Bespoke Air Pressure Stabilisers to function correctly.

-

Just a few details to fill in...

Air Pressure Stabilisers

APSX®-123 Air Pressure Stabiliser

- Operating range: 3 to 50pa

- Manufactured in the UK

- Approved & certified

- Serial Number Traceability

Air Pressure Stabilisers

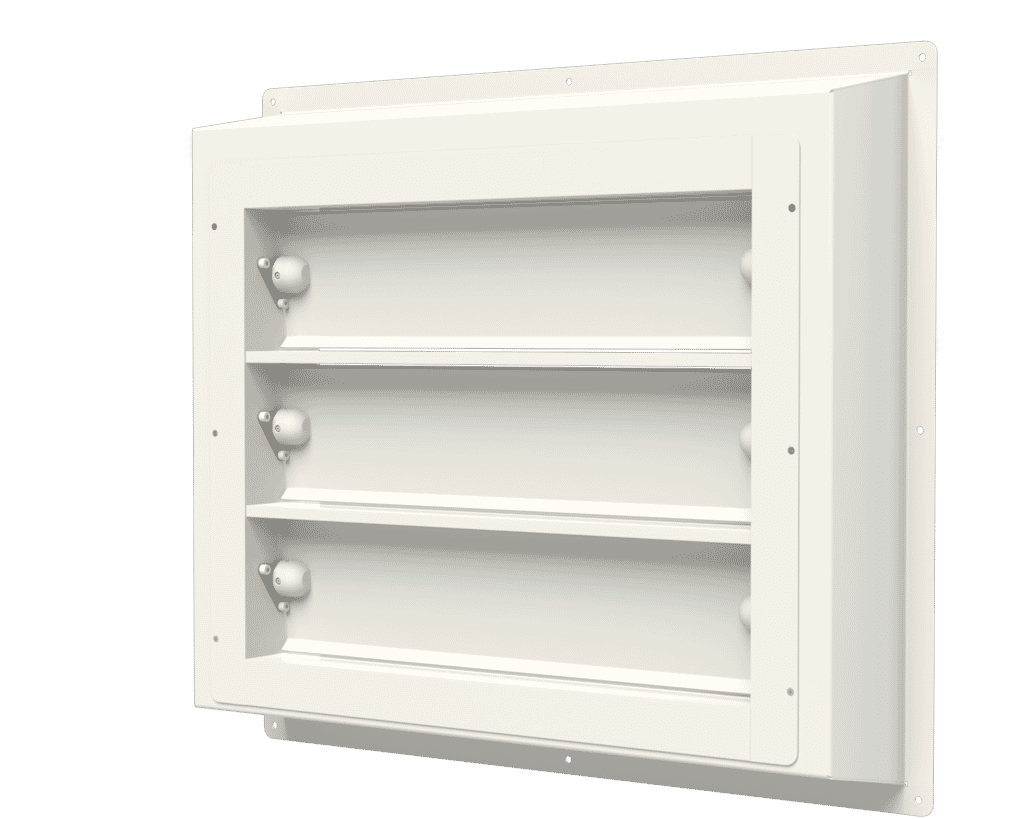

APSX®-FD Fire Rated Air Pressure Stabiliser

- Operating range: 3 to 50pa

- Manufactured in the UK

- Fire rating: 120 Minutes

- Serial Number Traceability

Air Pressure Stabilisers

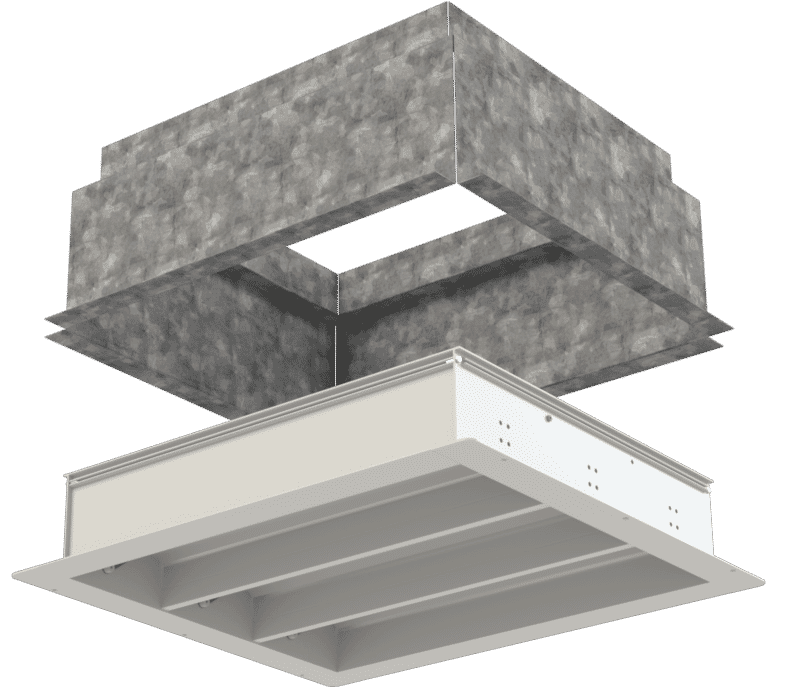

APSX®-C Ceiling Mounted Air Pressure Stabiliser

- Operating range: 3 to 30pa

- Manufactured in the UK

- Approved & certified

- Serial Number Traceability

Air Pressure Stabilisers

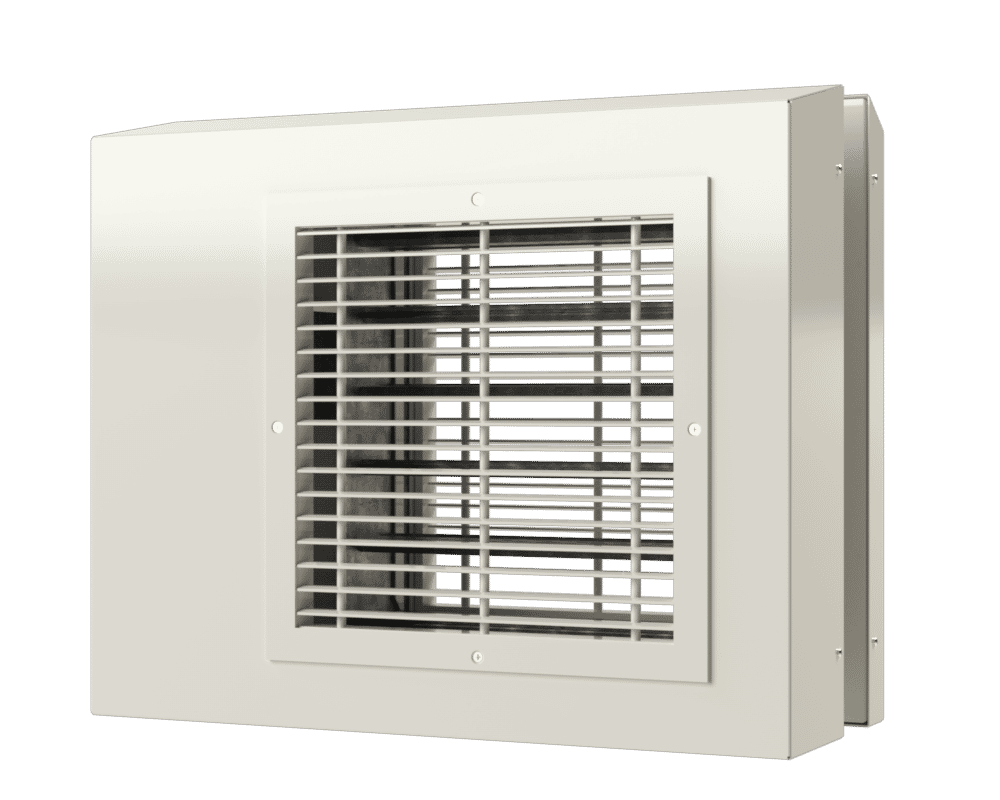

ATG-FSS Air Transfer Grille - Smoke/Fire Shutter

- Smoke/Fire Rating: 60 Minutes

- Serial Number Traceability

- Incorporating VARI-Fix® system

- Patent Pending

- Incorporating Smoke/Fire Damper

- Antimicrobial protection